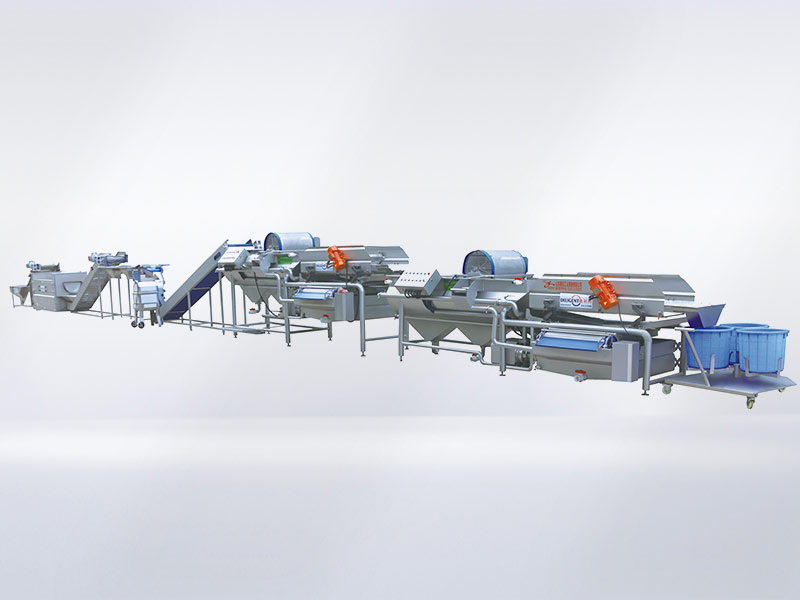

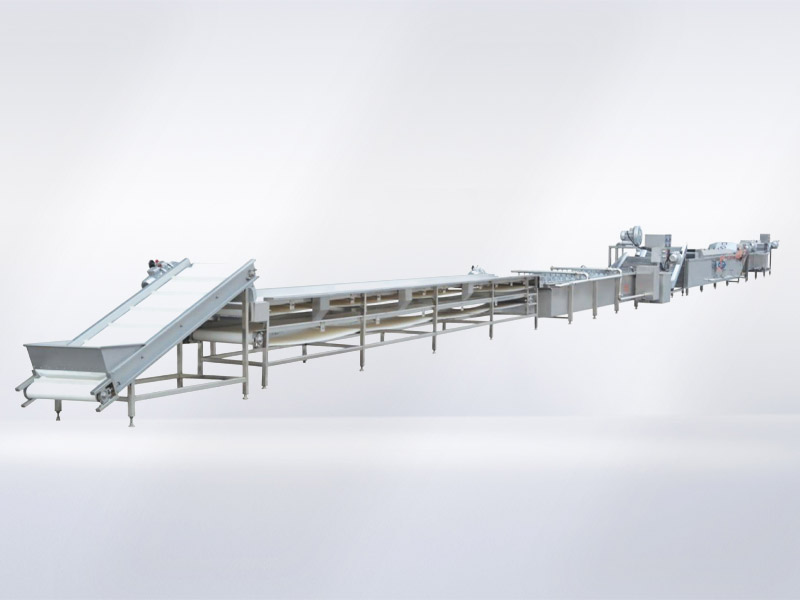

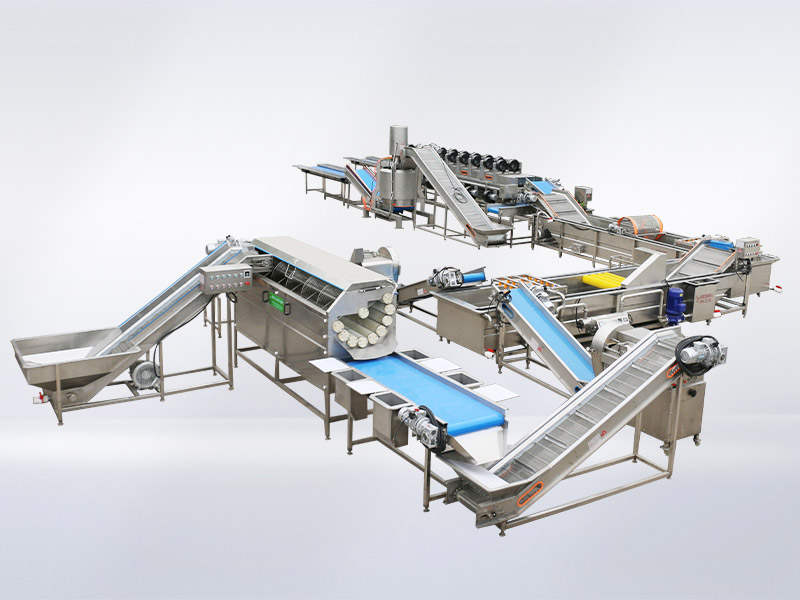

Complete Dehydrated Vegetable Processing Equipment

The complete set of equipment for dehydrated vegetable processing production line includes the process flow and method of hot air drying and dehydrated vegetable processing

1. The selection of raw materials should choose vegetable varieties with rich meat quality. Before dehydration, the best and worst should be strictly selected, and the parts with pests, diseases, rot, and shrinkage should be removed. It is advisable to reach 80% maturity, and over ripe or unripe vegetables should also be picked out. Except for melons, which have their seeds removed, other types of vegetables can be washed clean with water and then dried in a cool place, but should not be exposed to sunlight.

2. Cutting and blanching will cut the cleaned raw materials into pieces, threads, strips, and other shapes according to product requirements. During pre cooking, the ingredients may vary. For those that are easy to fully boil, blanch them in boiling water. For those that are difficult to fully boil, blanch them in boiling water for a while. The general blanching time is 2-4 minutes. Leafy vegetables should be soaked without blanching.

3. The entire equipment of the dehydrated vegetable processing production line should be cooled immediately (usually by rinsing with cold water) to quickly reduce the temperature of the vegetables after cooling, draining, and pre boiling treatment. After cooling, in order to shorten the drying time, a centrifuge can be used to shake water, or a simple manual method can be used to press and drain. After the water is drained, it can be spread out and slightly cooled for baking on a plate.

4. Drying should determine different temperatures, times, colors, and moisture content during drying according to different varieties. Drying is usually carried out in a drying room. There are roughly three types of drying rooms: * * simple drying rooms that use counter current air blowing for drying; The second method is to use a two-story double tunnel and a combination of upstream and downstream drying rooms; The third type is a box type stainless steel hot air dryer, with a drying temperature range of 65 ℃ -85 ℃, which is dried at different temperatures and gradually cooled down. When using the second type of drying room, evenly spread the vegetables on a plate, then place them on a pre-set drying rack, maintain a room temperature of about 50 ℃, and constantly flip them to accelerate drying. The general drying time is about 5 hours.

5. After inspection and packaging, dehydrated vegetables that meet the requirements of the Food Hygiene Law can be packaged in plastic bags, sealed and boxed, and then put on the market.

6. The complete set of equipment for dehydrated vegetable processing production line. The physical characteristics of dehydrated vegetables: After dehydration, the moisture content of vegetables drops to 4% -13%, and the water activity drops to about 0.17, which makes microorganisms and enzymes inactive. The product can be stored for a long time for 2-3 years by sealing or vacuum packaging. Compared with fresh raw materials, the weight is reduced by 10-20 times. The product can generally be re fresh within 3-10 minutes with a rehydration ratio of 1:3.5-0.5, and the re freshness is greater than 90%. In addition, vegetable dehydration creates unfavorable environmental conditions for microbial growth, preventing the growth and reproduction of microorganisms, especially pathogenic bacteria, and achieving the effect of * * and preservation. Chemical characteristics of dehydrated vegetables: After dehydration of vegetable cell tissues, protein chemical properties change, cell membrane permeability is enhanced, cell structure and function change, cell hydrolysis occurs, and some storage substances and structural substances, such as starch, sugar, protein, fruit acid, and a small amount of fat substances, are broken down into simple substances under the action of enzymes. Starch is broken down into glucose, disaccharides are converted into monosaccharides, proteins and peptides are broken down into amino acids, and the original fruit acid is broken down into gluc acid. This change can improve the flavor of vegetables after dehydration, increase freshness and sweetness, and result in greater loss of soluble and unstable components, while insoluble components and mineral losses are relatively small.

Leave a reply