Pre-processing Equipment for Crispy Fruit and Vegetable Cleaning

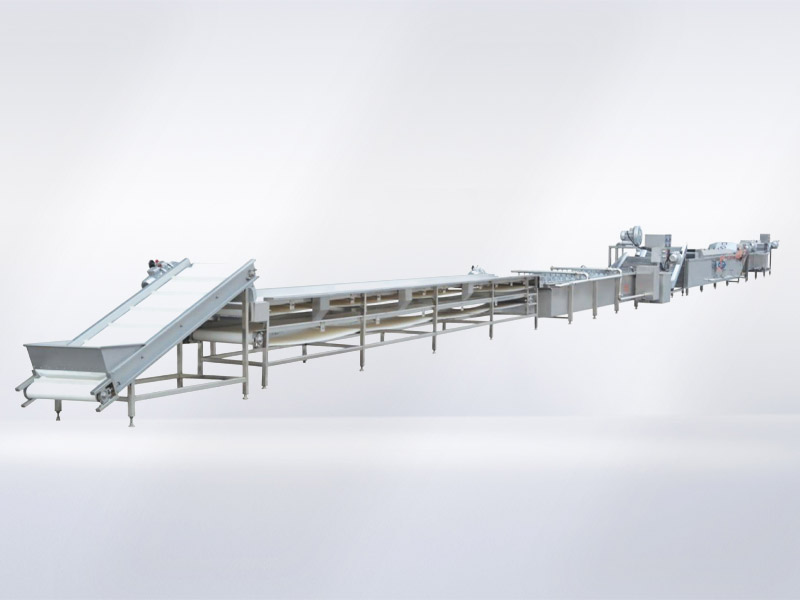

Related equipment 1: Multi functional bubble cleaning machine

The bubble cleaning machine adopts a water bath type bubble cleaning. The material undergoes irregular and strong flipping motion in the water due to the churning effect generated by the release of bubbles. The movement of the material effectively separates the surface attachments of the cleaned object, simulating the basic action of manual cleaning. At the same time, due to the churning motion of the material generated in the steam water mixture, it effectively avoids the damage to the material caused by collisions, knocks, scratches, etc. during the cleaning process, improves work efficiency, and turns manual operation into mechanized processing.

The cleaning machine has added a spray cleaning function during the material conveying process, which allows the material to undergo spray cleaning after completing the soda bath cleaning. The function of this process is to replace and remove dirty water on the surface of the material, improving the cleaning effect of the material. At the same time, the external cleaning spray water automatically flows into the water bath after the material is cleaned again, replacing and supplementing the cleaning water in the water bath, maintaining the cleanliness of the water in the water bath, and improving the utilization rate of the cleaning water while increasing the cleaning effect.

Application of Fruit and Vegetable Bubble Cleaning Machine:

The fruit and vegetable bubble cleaning machine is suitable for cleaning, soaking, sterilizing, disinfecting, and fixing granular, leaf shaped, and root and stem products such as leafy vegetables, edible fungi, fruits, aquatic products, etc. The bubble cleaning machine adopts advanced water treatment technology, and the cleaning water is recycled, which can save 80% of the cleaning water.

Main features of fruit and vegetable bubble cleaning machine

1. The bubble cleaning machine has the characteristics of high cleaning efficiency, energy saving, water saving, equipment stability, and the ability to maintain the original color under the joint work of bubble, surfing, lifting, spraying, etc.

2. Except for standard components such as motors and bearings, the equipment is made of food grade materials, which fully comply with export food hygiene requirements.

3. The conveying part of the bubble cleaning machine adopts SUS304 stainless steel mesh belt, which is smooth and adjustable in speed. The material moves along with the conveyor belt, which can avoid damage to the conveyed material.

4. Easy to operate, convenient to maintain, and easy to connect.

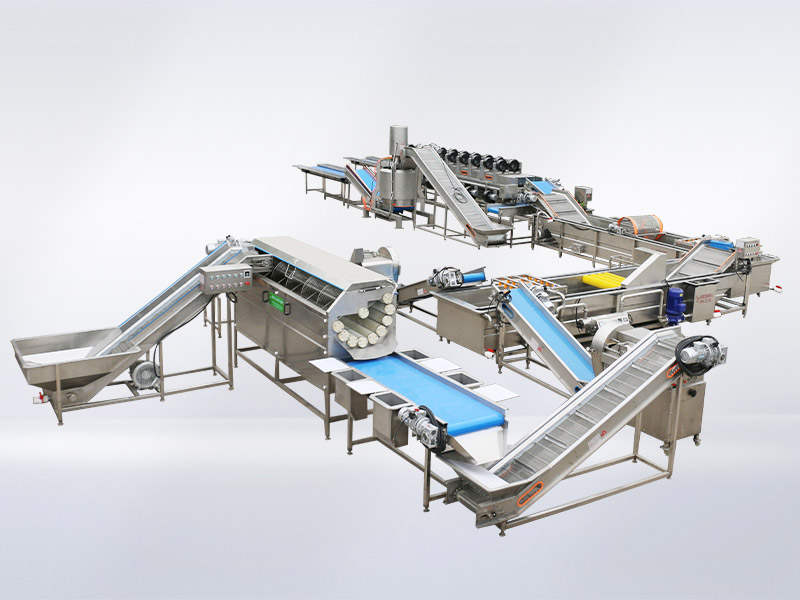

Related equipment 2: Fruit and vegetable slicer

This machine is mainly used for slicing fruits and vegetables, and can process potatoes (potatoes), lotus roots, apples, pears, etc. The products cut by this machine have neat shapes and uniform thickness, with a yield rate of 99%, meeting the processing needs of export products. The equipment has a reasonable structure, low failure rate, easy maintenance, and is suitable for food export processing enterprises, refrigeration enterprises, and vegetable processing enterprises.

Related Equipment 3: Fruit Peeling and Core Removal Machine

(1) The main material of the chassis shell of this machine is 304 stainless steel, and the control system includes PLC servo motors and drives from Mitsubishi in Japan and Delta in Taiwan, as well as inverter from Envision. Yadeke cylinder/solenoid valve, electrical appliance is Delixi. (Optional according to user requirements).

(2) Can simultaneously perform three actions: peeling, puncturing, and slicing.

(3) Automatically finding fruit height and fruit thickness, therefore it has good adaptability to irregular fruit shapes.

(4) Main technical parameters:

(5) Processing capacity: 40 pieces/minute Peel thickness: 1.1-1.3mm Adjustable fruit diameter: 65-110mm

Core removal diameter: 22mm (can be customized according to user requirements) Power: 1.3kw Air consumption: 0.30 cubic meters per minute Peel removal rate: ≥ 95 ° (normal apple, non rotten fruit, dry scar, irregular fruit) Excluding weight at both ends: 380 kilograms

Leave a reply