Intelligent Air Energy Continuous Dryer

The air energy intelligent continuous dryer is a new type of energy-saving dryer. Its working principle is based on the reverse Carnot cycle principle, using a small amount of electrical energy and a compressor to evaporate the working medium into a gaseous state in the evaporator after passing through an expansion valve, and absorb a large amount of heat energy from the air. The gaseous working medium is compressed by the compressor into a high-temperature and high-pressure gas, and then enters the condenser to release heat, heating the drying medium. By continuously cycling and heating, the drying medium can be heated to 40 ℃~75 ℃. Compared to electric dryers, it saves two-thirds of electricity.

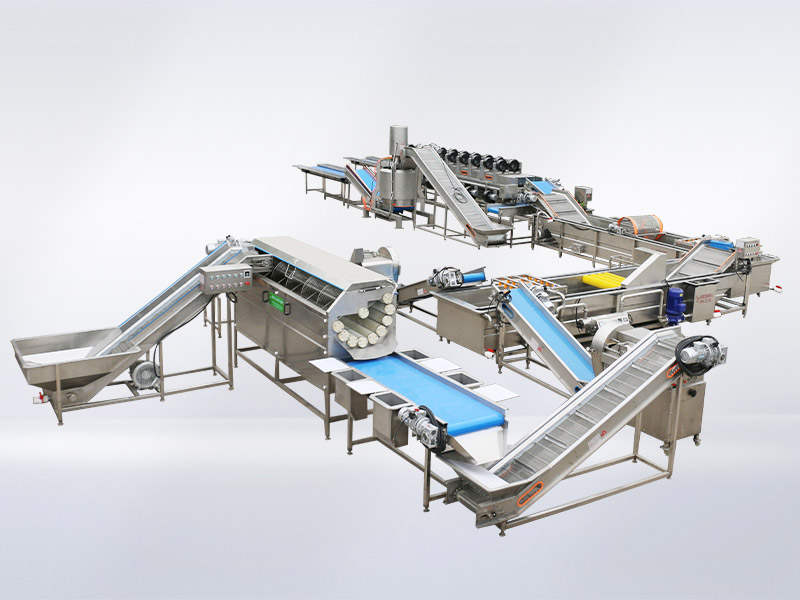

Air powered continuous drying equipment, an intelligent device that integrates heating, cooling, exhaust temperature, and ventilation, is a new type of energy-saving and emission reducing drying equipment. The product is easy to install, safe to operate, and has a long service life.

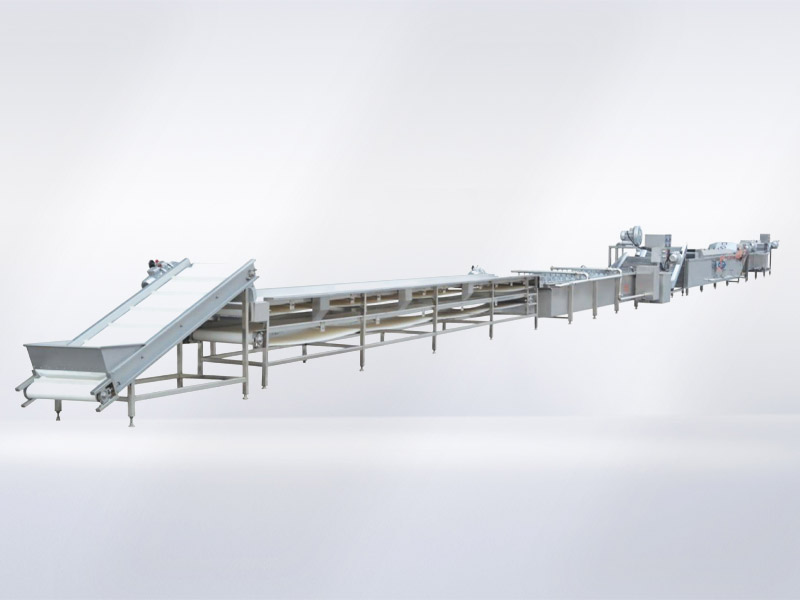

This machine can effectively remove moisture from fruits, vegetables, and other products, making it suitable for assembly line operations and improving the automation level of enterprises. The drying air temperature is generally adjustable from 40-70 degrees Celsius, effectively protecting the color and quality of the materials themselves. This machine is mainly suitable for drying products such as vegetables and fruit products.

The transmission of this machine adopts a speed regulating deceleration motor, which makes the drying effect of the product adjustable and the mesh conveyor belt runs smoothly.

advantage:

The drying area is equipped with multiple independent temperature control systems for more uniform heating. To prevent the mesh conveyor belt from sinking due to excessive weight of materials, support rollers and guide rails are installed below the middle of the mesh belt. There are perspective windows on both sides of the feeding and discharging areas, which allow for observation of materials during production. The machine is equipped with multiple movable doors for easy cleaning and maintenance during equipment shutdown.

This production line consists of two main functional sections: heat pump and high flow fan. It adopts independent control of the operating speed of the mesh conveyor belt to adjust it reasonably according to the actual production situation and meet the actual production needs.

Leave a reply