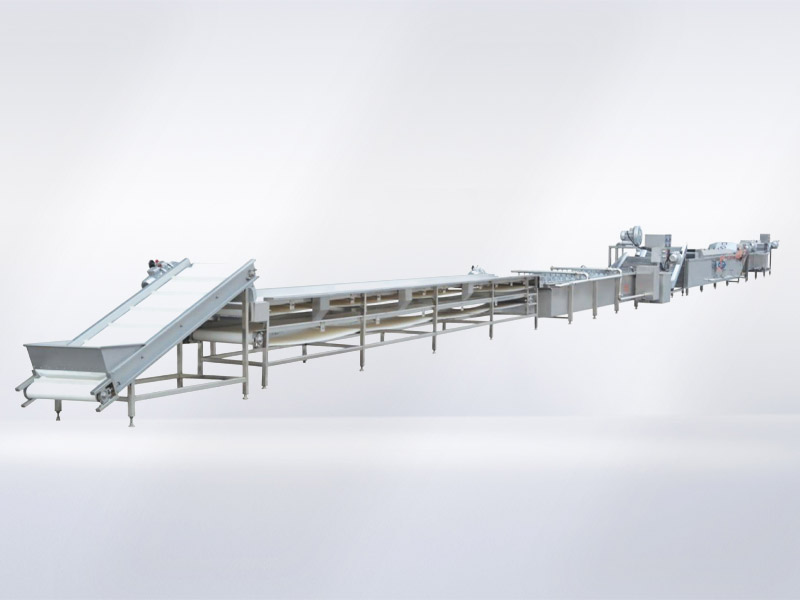

Multi-layer Continuous Dryer

This production line consists of three main functional sections: heat exchanger machine, high flow fan, and wind dryer. It adopts independent control of the operating speed of the mesh belt to adjust it reasonably according to the actual production situation and meet the actual production needs.

1. Drying machine: total length 22000mm, effective operation of mesh belt 1900mm.

(1) Using steam heating, the temperature is set by a thermostat and can be adjusted within the range of 30-80 ℃,

(2) Conveyor belt: Made of stainless steel woven mesh belt, with chains on both sides and reinforced shafts every 305mm in the middle, with a mesh spacing of 10X15mm and a thread diameter of Φ 2.0mm. The effective width of the mesh belt is not less than 1900mm. The mesh belt motor adopts a frequency converter for stepless speed regulation, and the conveying time of the mesh belt in the drying tank can be adjusted freely within 30-90min to meet the needs of drying different specifications of products. The specific parameters of the mesh belt are as follows:

The diameter of the shaft is not less than Φ 10mm stainless steel round steel;

The diameter of the transmission sprocket is about Φ 183mm;

The chain has a double pitch with a pitch of 50.8mm.

(3) Using a stainless steel tank body with an inner layer thickness of 2.0mm and a 50 × 50 × 1.5mm stainless steel square tube,

Use 1mm stainless steel plate as the outer protective plate; Tilt the bottom plate and open a square observation window on one side to facilitate thorough drying of the interior of the equipment; In order to minimize the loss of steam, a cover plate is installed on the upper part of the tank (the product inlet and outlet positions can be observed), and exhaust ports with a diameter of 150mm are opened at both ends to collect residual steam and discharge it outdoors through a connecting pipe; The bottom of the tank is equipped with stainless steel adjustment feet for adjusting the installation height of the equipment.

(4) The regulating valve and globe valve are made of domestic famous brands.

(5) The drying host is equipped with about 5 centrifugal fans, with a power of 7.5KW/unit; Equipped with approximately 5 axial flow fans, power: 1.1KW; 2 conveyor motors, 2.2kw and 1.5kw respectively

Advantages: The drying area is equipped with multiple independent temperature control systems for more uniform heating. To prevent the mesh belt from sinking due to excessive weight of materials, support rollers and guide rails are installed below the middle of the mesh belt. There are perspective windows on both sides of the feeding and discharging areas, which allow for observation of materials during production. The machine is equipped with multiple movable doors for easy cleaning and maintenance when the equipment is shut down. Each floor is tensioned with independent mesh belts for future equipment maintenance.

Leave a reply