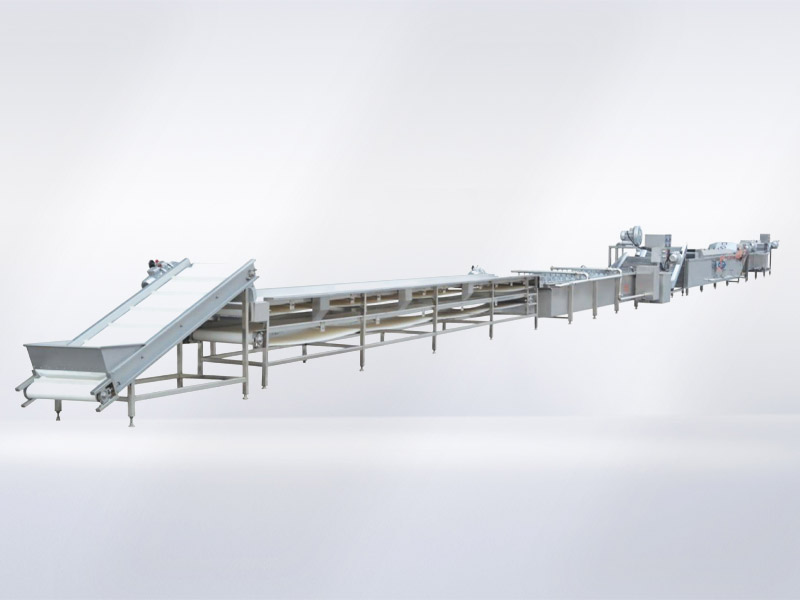

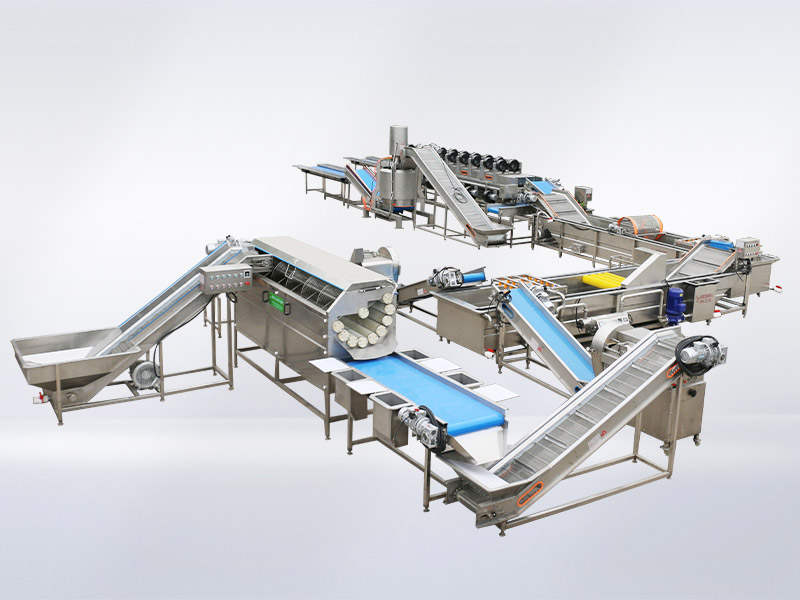

Bottle-filled Pasteurization and Cooling Line

1、 Scope of application:

This machine uses steam to heat water, and the temperature is set by a thermostat. The water temperature can be adjusted within the range of 60-96 ℃, which not only has a sterilizing effect, but also ensures that proteins do not fluctuate and denature within a large temperature difference range, and the original nutritional components of food are not affected. Suitable for food processing enterprises to use for pasteurization and cooling of food in glass bottles. For example: PE material bottles, cans, glass bottle products, pickled vegetables and related products. And improve the shelf life and reduce labor intensity.

2、 Characteristics:

1. This machine is composed of two parts: a sterilization section and a cooling section, which use circulating hot water. The sterilization temperature can be adjusted to ensure that the container does not break and the sterilization quality is guaranteed. It has the advantages of preventing bottle explosion, continuous production, uniform temperature, automatic temperature control, low power consumption, hot water circulation, and easy maintenance, making it an ideal equipment in the food processing industry. It has the advantages of automatic sterilization temperature control and infinitely adjustable sterilization time, and is widely used for sterilization and cooling of various bottled and canned acidic fruit juice drinks, electrolyte drinks, alcoholic beverages, seasonings and other products.

2. This machine adopts high-temperature resistant plastic chain plate conveyor, designed in imitation of Germany, and is detachable. The belt has a flat surface and low friction coefficient, which can prevent scratches on the bottom of three piece cans and easy to pull cans. The mesh belt meets the hygiene requirements of the product. The spray nozzle adopts a special atomizing nozzle, which evenly atomizes and sprays on the packaging container to prevent damage to the packaging container; This machine realizes automatic bottle feeding and discharging, achieving complete automation of the production line. The body is made entirely of SUS304 material, which is beautiful, sophisticated, stable in operation, and easy to use.

3. The pipeline pump valve is manually controlled. During the operation of the equipment, water is being recycled, and the water pump valve must always be in the open state. The valve is used to control the flow of water, not the opening and closing of water. Valves do not need to be repeatedly closed and opened during the working process.

4. Automatic water replenishment and drainage are both controlled by liquid level sensors, and the liquid level is controlled by compressed air to control the angle seat valve.

5. The overflow water in the cooling section can be recycled through the cooling tower, and an interface is reserved at the inlet of the equipment. The cooling tower needs to be provided by the user.

6. The steam in the sterilization section is controlled by pneumatic automatic control. The working principle is to control compressed air through an electromagnetic valve, and then control the opening and closing of steam through compressed air. When the water temperature in the sink is lower than the set value, the steam control valve automatically opens to introduce steam, thereby raising the water temperature to the set temperature. When the water temperature rises to the set value, the steam control valve will automatically close.

Leave a reply