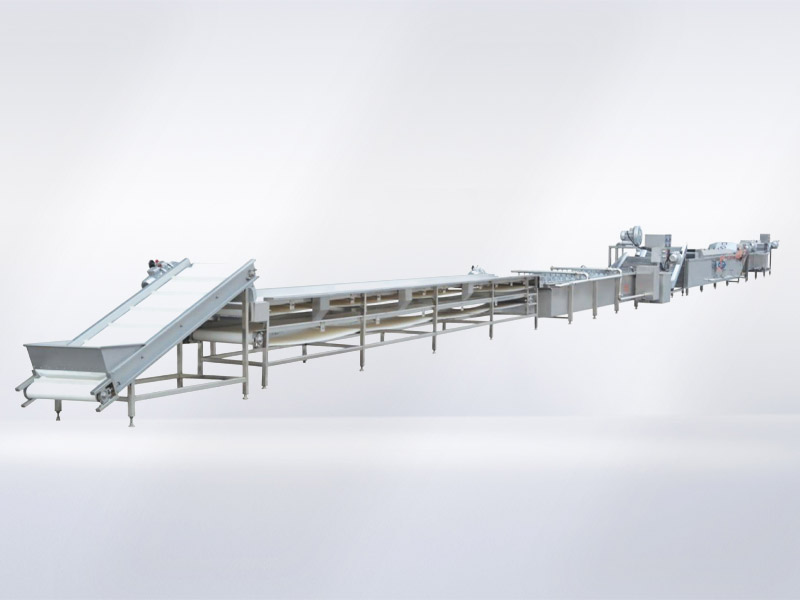

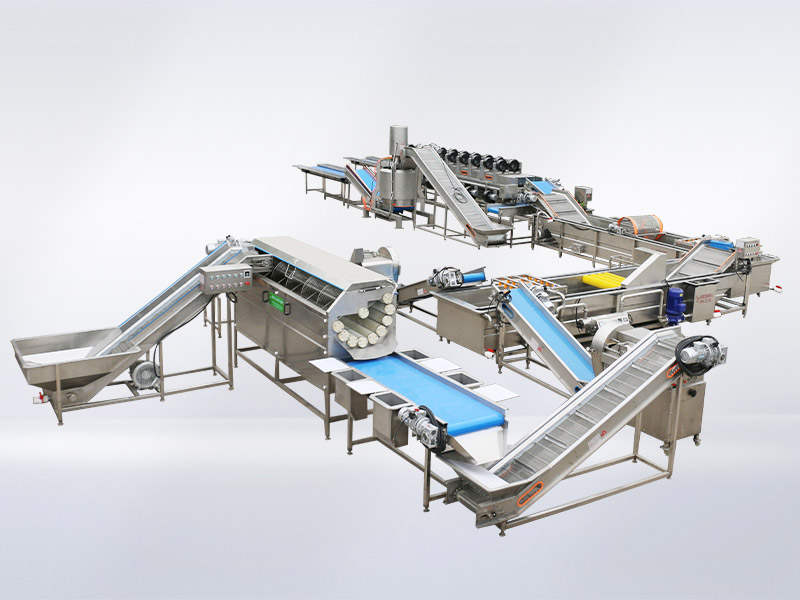

Pasteurization and Drying Production Line

This machine uses hot water as the medium and is divided into two parts: a sterilization tank and a cooling tank. It can be made of stainless steel as a whole, with stepless variable frequency speed regulation, low noise, and smooth operation. The temperature and time can be adjusted arbitrarily according to the requirements of the packaging. The machine has a compact structure, easy operation, and low failure rate. The heating method uses boiler steam or boiler hot water, which is particularly suitable for continuous sterilization operations.

1、 Scope of application of pasteurizer:

The water bath pasteurizer is suitable for use in food processing enterprises and can pasteurize soft packaging and glass bottles of food and beverages. For example: fruit juice, jam, pickled vegetables, boiled vegetables, wild vegetables, seasonings, and related products. And improve the shelf life and reduce labor intensity.

characteristic

1. The equipment tank body is made of SUS304 stainless steel and adopts a frame structure that is not easily deformed, which meets the national food production safety standards.

2. The equipment is covered with a water tight seal to prevent steam from escaping and scalding the operators. At the same time, the product is insulated and the sterilization temperature is ensured to be uniform.

3. Variable frequency reducers are used at both ends of the equipment, and a frequency converter is used in the middle to drive the transmission shaft forward and backward, reducing the tension of the transmission device and enabling the conveyor belt to operate. This can not only save 60% energy, but also reduce the tension of the mesh belt and extend its service life.

4. The conveyor belt can be selected from three types based on the customer's product situation: stainless steel chain mesh, stainless steel chain plate, and PP chain plate. * * can be added on both sides of the conveyor chain (chain plate) to prevent products from getting caught in the chains on both sides of the chain plate.

5. The steam heating system mainly consists of automatic temperature control valve, shut-off valve, manual fine adjustment valve, temperature sensor, display screen, etc.

6. The equipment adopts steam heating, and the water temperature quickly reaches the predetermined temperature, which is conducive to energy conservation, noise reduction, and relatively long service life.

7. The temperature display instrument can adjust the steam size to ensure a small temperature difference in the water inside the tank and uniform sterilization effect. Temperature sensors can monitor temperature values.

Leave a reply