Continuous Dryer

The air energy intelligent dryer is an energy-saving dryer. Its working principle is based on the reverse Carnot cycle principle, using a small amount of electrical energy and a compressor to evaporate the working medium into a gaseous state in the evaporator after passing through an expansion valve, and absorb a large amount of heat energy from the air. The gaseous working medium is compressed by the compressor into a high-temperature and high-pressure gas, and then enters the condenser to release heat, heating the drying medium. By continuously cycling and heating, the drying medium can be heated to 30 ℃~70 ℃. Compared to electric dryers, it saves two-thirds of electricity.

Air drying equipment, an intelligent device that integrates heating, cooling, exhaust temperature, and ventilation, is a new type of energy-saving and emission reducing drying equipment. The product is easy to install and has a long service life.

Main principles

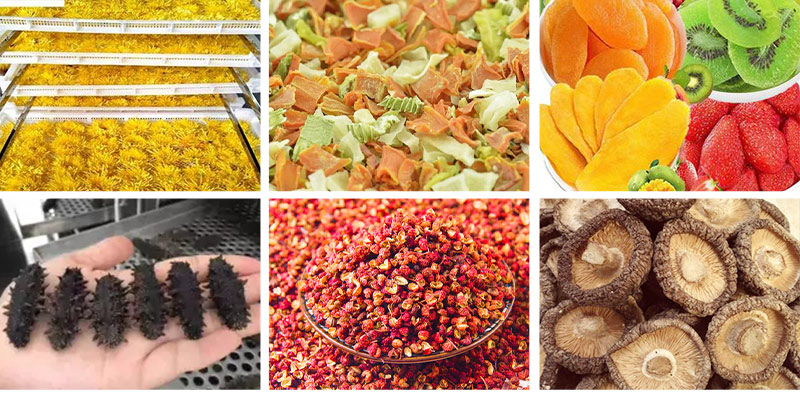

Multi layer drying line is a batch and continuous production drying equipment used for dehydration and drying of processing materials such as fruit and vegetable chips, dehydrated vegetables, and traditional Chinese medicine. The device has a compact structure, simple operation, and easy maintenance. The main heating method is air source heat pump. It can save 65-75% energy consumption.

working principle:

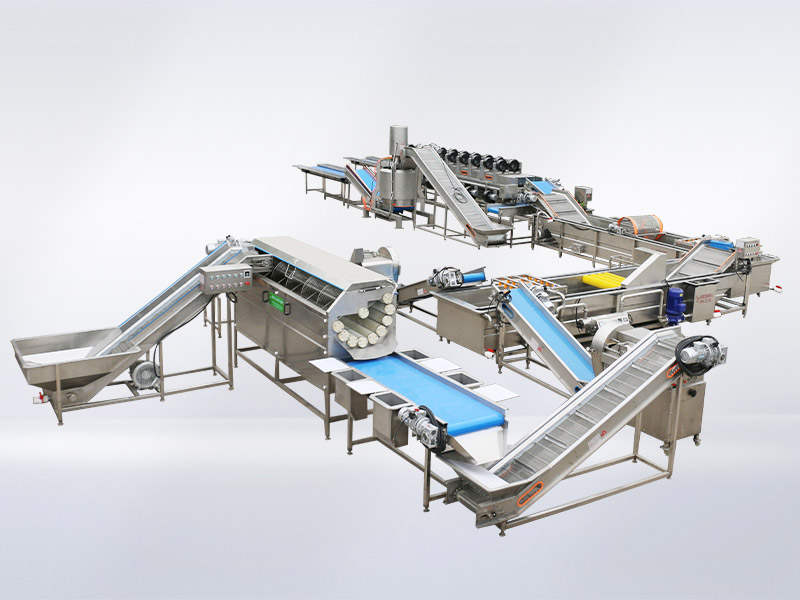

The material is transported to the drying area through a mesh conveyor belt, and as the conveyor belt runs, the temperature of the material gradually rises to the set temperature. The humid air is discharged outside through a dehumidification fan. The hot air circulation system takes air from one side of the drying area, passes it through a heat exchanger, is pressurized by a centrifugal fan, and passes through the material from the other side to achieve the purpose of drying. The circulating fan adopts axial flow fan, and the fan adopts high temperature resistant type, which is easy to maintain and replace. The equipment is equipped with a single vertical control cabinet, which is controlled by PLC program. The equipment automatically adjusts and controls temperature, automatically forces dehumidification, and uses Chint electrical appliances for low voltage.

This machine can effectively remove moisture from fruits, vegetables, and other products, making it suitable for assembly line operations and improving the automation level of enterprises. The drying air temperature is generally adjustable from 40-70 degrees Celsius, effectively protecting the color and quality of the materials themselves. This machine is mainly suitable for drying products such as vegetables and fruit products.

The transmission of this machine adopts a speed regulating deceleration motor, which makes the drying effect of the product adjustable and the mesh conveyor belt runs smoothly.

advantage:

The drying area is equipped with multiple independent temperature control systems for more uniform heating. To prevent the mesh conveyor belt from sinking due to excessive weight of materials, support rollers and guide rails are installed below the middle of the mesh belt. There are perspective windows on both sides of the feeding and discharging areas, which allow for observation of materials during production. The machine is equipped with multiple movable doors for easy cleaning and maintenance during equipment shutdown.

This production line consists of two main functional sections: heat pump and high flow fan. It adopts independent control of the operating speed of the mesh conveyor belt to adjust it reasonably according to the actual production situation and meet the actual production needs.

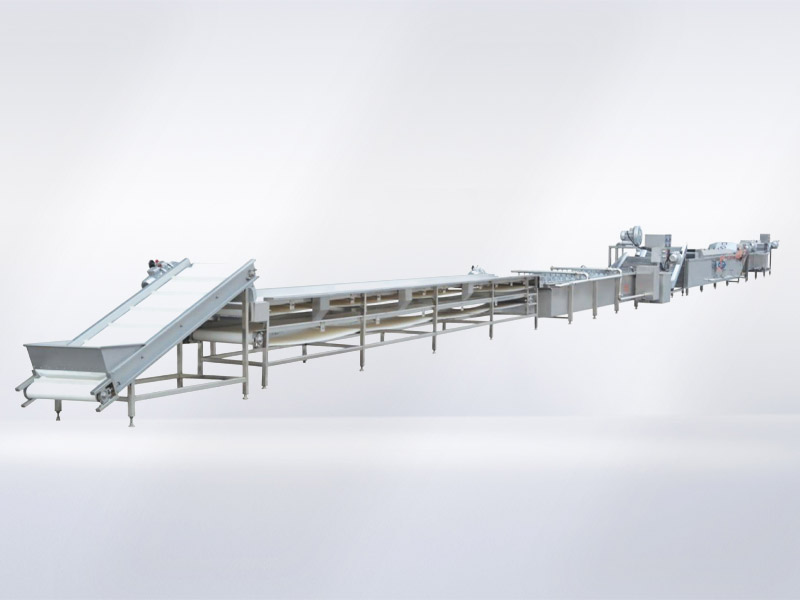

1. Drying machine: total length of 30000mm, effective operation of mesh conveyor belt 3000mm.

2. Equipment material: The outer shell and inner wall are both made of cold storage panels, and new insulation materials are used to fill the space between the inner and outer panels.

3. Conveyor belt: Stainless steel mesh conveyor belt is used, with chains on both sides, and the conveyor belt width is not less than 3000mm. The conveyor belt motor adopts a frequency converter for stepless speed regulation, and the conveying time of the conveyor belt in the drying tank can be adjusted arbitrarily to meet the needs of drying different specifications of products.

Leave a reply