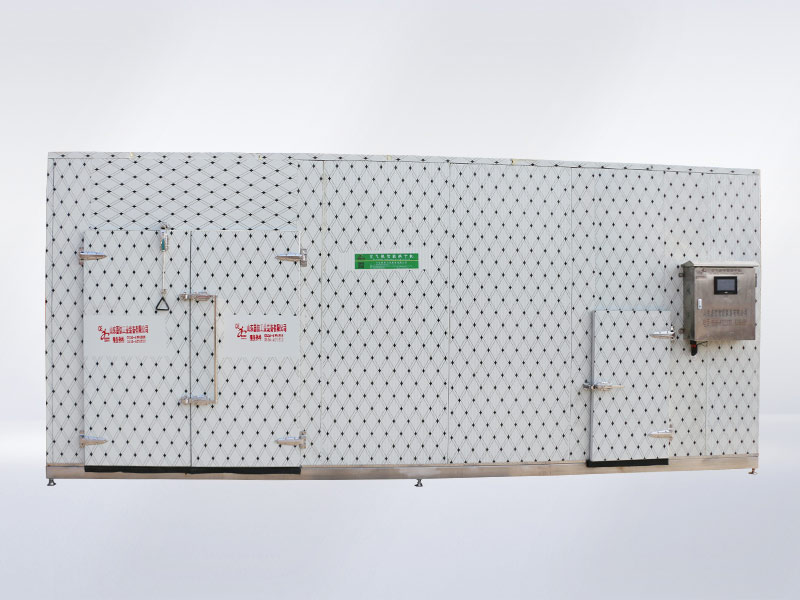

Chinese Herbal Medicine Dryer

The drying method of traditional Chinese medicine decoction pieces is directly related to the quality of the decoction pieces. The traditional drying method is natural drying, which refers to placing the cut decoction pieces in sunlight or in a cool and ventilated place to dry in the shade. The advantages are economic convenience and low cost, but the disadvantages are that it occupies a large area, is easily affected by climate, and hygiene conditions cannot be guaranteed. Decoction pieces with fragrant odor and high volatile components are prone to discoloration and oil loss, while general decoction pieces require maintaining their shape, color, aroma, and taste. Therefore, traditional drying methods cannot meet the drying requirements of decoction pieces.

The air powered traditional Chinese medicine decoction piece dryer is a closed drying environment that ensures the hygiene requirements of the materials. It circulates in a hot air box, saves energy, has a short drying time, high drying efficiency, and does not require flipping of the materials during the drying process, saving labor. The equipment adopts a PLC intelligent control system, which can flexibly set the drying temperature, humidity, time, etc. according to the pharmacological characteristics of the decoction pieces, ensuring the medicinal properties, appearance, color, etc. of the dried traditional Chinese medicine decoction pieces, allowing them to fully exert their therapeutic effects.

The drying temperature for general decoction pieces should not exceed 80 ℃, and for decoction pieces containing aromatic volatile compounds, it is advisable not to exceed 50 ℃. After drying, the decoction pieces should be cooled before storage. Otherwise, the residual heat can cause the decoction pieces to regain moisture and be prone to mold growth. After drying, the moisture content of the decoction pieces should be between 8% and 12%.

Product advantages:

1. Efficient

The equipment box adopts a fully enclosed structure, with hot air circulating inside the box, greatly reducing the drying time of materials and ensuring product output.

And it is easy to install and demolish, occupies a small area, and can be installed indoors or outdoors.

2. Energy saving

The device only needs to consume a small amount of electricity to absorb a large amount of heat in the air, with a power consumption of only 1/4 of that of an electric heater; Compared with coal-fired, oil fired, and gas-fired dryers, it can save about 70% of operating costs. 1 kWh of electricity is equal to 4 kWh of electricity.

3. Environmental Protection

During the operation of the equipment, no waste heat, exhaust gas, combustion materials, or emissions are generated, and there are no hazards such as flammability, explosiveness, poisoning, or short circuits that may exist in traditional dryers.

4. Security

The device is equipped with multiple safety protection functions, including phase sequence protection, phase loss protection, overload protection, high and low voltage protection, etc. The water and electricity are completely separated, and there are no safety hazards.

5. Hygiene

Due to its closed cycle, it is particularly important to avoid impurities that may contaminate the materials caused by gas exchange with the outside world, especially for food, medicine, or biological products.

6. Intelligent

The equipment is free of manual operation, does not require dedicated supervision, and materials do not need to be flipped. It is intelligently controlled for drying time, * * time, stable performance, and easy operation. Multiple time periods can be set according to the characteristics of the material, and different temperatures can be used to dry the material. It can store 10 drying process parameters.

Leave a reply