Soft Packaging Low-temperature Pasteurization Machine

1、 Main principle:

Pasteurization, also known as low-temperature disinfection or cold sterilization, is a disinfection method that uses lower temperatures to kill bacteria while maintaining the flavor of nutrients in the item. It is now widely used to define heat treatment methods that require the killing of various pathogens.

Within a certain temperature range, the lower the temperature, the slower the bacterial reproduction; The higher the temperature, the faster the reproduction (the suitable temperature for microbial growth is generally 28 ℃ -37 ℃). But if the temperature is too high, bacteria will die. Different bacteria have different suitable growth temperatures and heat and cold resistance abilities. Pasteurization is actually the process of using the characteristic of pathogens that are not very heat-resistant, and treating them with appropriate temperature and insulation time to completely kill them. But after pasteurization, a small amount of harmless or beneficial, heat-resistant bacteria or bacterial spores were still retained.

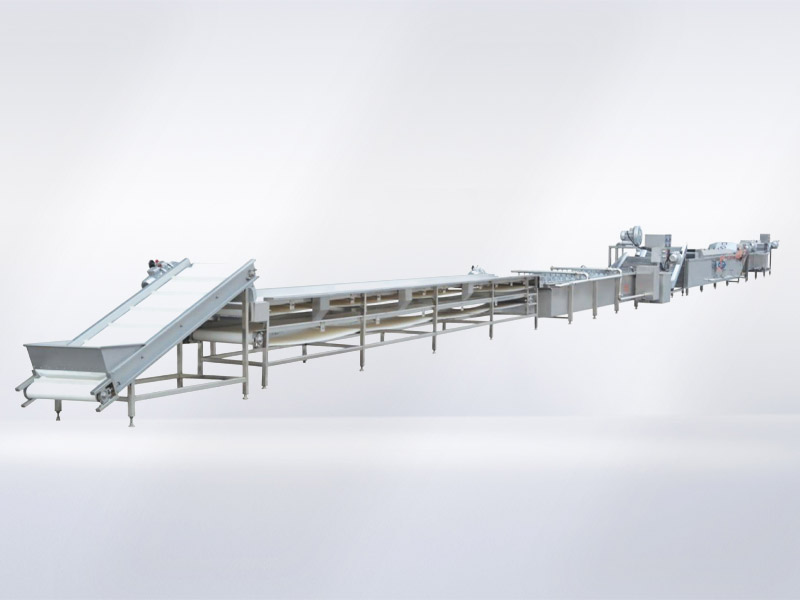

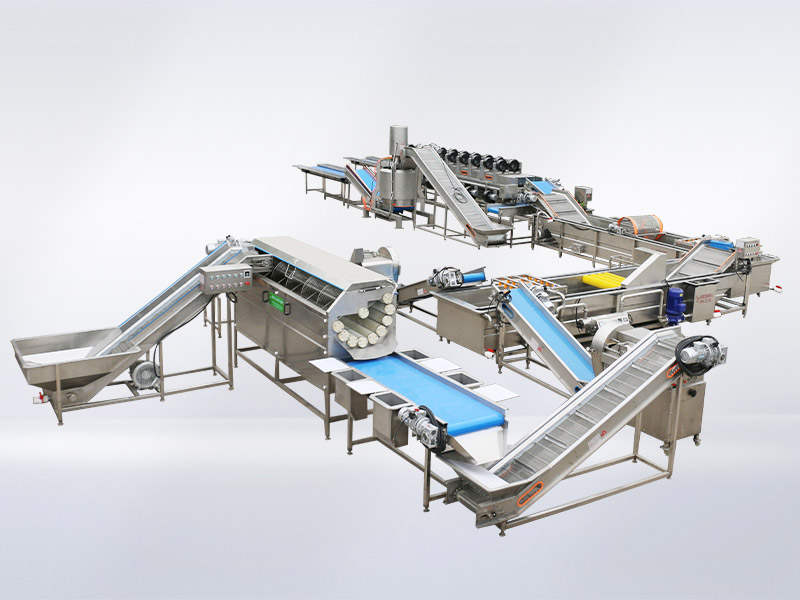

2、 Equipment Introduction:

Using food grade materials. Smooth conveying, adjustable speed, and material movement along with the conveyor belt can avoid damage to the conveyed material. Low noise, suitable for work environments that require quietness. The structure is simple and easy to maintain. Low energy consumption and low usage cost.

The equipment is equipped with a floating pressure mesh belt, which can prevent the product from floating and being stuck in water due to buoyancy. This machine uses hot water as the medium and is divided into two parts: a sterilization tank and a cooling tank. The overall material is made of 304 stainless steel, and the temperature and time can be adjusted according to the requirements of the packaging. The machine has a compact structure, easy operation, and low failure rate. The heating method uses boiler steam, which is particularly suitable for continuous sterilization operations. The equipment adopts a manually controlled temperature system, which heats up the water quickly, evenly, and has a small temperature difference. The temperature can be adjusted, making it suitable for continuous pasteurization of different products. The water bath sterilization function can effectively mix materials evenly in the medium water, providing sterilization effect on items. The adjustable speed conveying system can effectively control the sterilization time of products and complete the sterilization process of products in a qualified manner.

Regularly change the water.

3、 Equipment advantages:

1. Temperature control system; It can be controlled automatically or manually,

2. Insulation system; Equipped with an internal circulation insulation system to reduce the opening frequency of the angle seat valve and extend its service life.

3. By using a dedicated variable frequency motor, automatic control can be achieved, and the motor is equipped with power compensation and forced cooling to extend its service life.

4. The sewage system should be cleaned and the bottom of the box should be kept clean.

5. The cooling system adopts high-pressure spraying.

6. The hot water circulation system is equipped with hot water circulation pipes to ensure consistent water temperature inside the tank.

Leave a reply