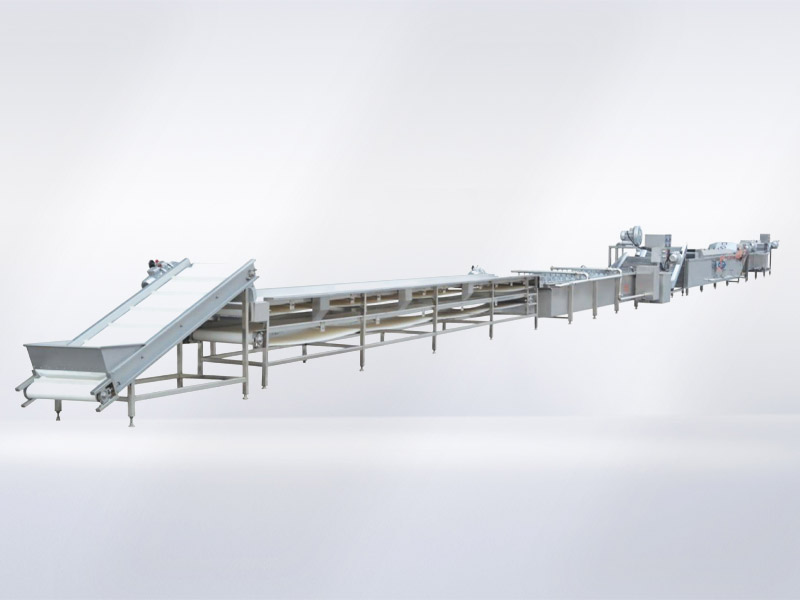

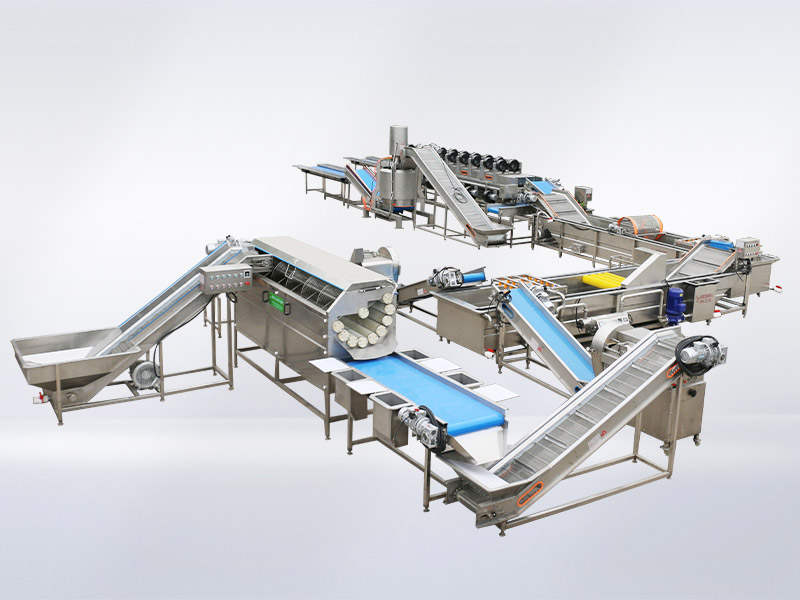

Blanching, Braising, Marinating and Defrosting Production Line

Steaming and boiling (hot water) line is an automated equipment designed by our company according to customer needs and material characteristics. After steaming (boiling water), the material can produce a peculiar odor, which tightens the internal structure of the material and prevents the loss of the aroma of the brine. The equipment adopts variable frequency rotation and double-layer mesh chain, with stable conveying speed, achieving the purpose of automatic continuous production, and can be adjusted at any time. In addition, the conveying network adopts high-strength and high-quality stainless steel, with a sturdy structure and heavy material bearing capacity, greatly improving production efficiency. This device has a beautiful appearance, reasonable structure, and easy operation, making it your ideal choice. The whole machine is made of SUS304 stainless steel, and the cooking temperature and speed can be set according to the process requirements. The machine runs smoothly, has low noise, small elasticity, is not easily deformed, and is easy to maintain. The water temperature is automatically controlled by a temperature controller, and the speed is adjusted by variable speed.

Scope of application:

Mainly suitable for the meat and food industry, such as chicken, beef, pork, poultry, fish, as well as dehydrated vegetables, seaweed shreds, squid, roots and other products, continuous boiling (soaking) can be matched with assembly line operations such as braising, coloring, and surface air drying equipment.

technological process:

Thawing → Bubble cleaner → Vibration draining → Product (brine) cooking → Cooling → Cleaning → Drying

Leave a reply